Embedded Automation Technology

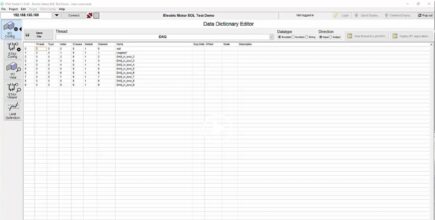

STAX Automation Technology is an embedded software framework that bridges the gap between traditional PLC automation and PC-based programming. STAX enables control and high-speed data acquisition and processing to be combined into one hardware platform, all while maintaining the configurability of a typical PLC by plant personnel. By consolidating functionality and taking advantage of advances in computing power, STAX provides cutting-edge capability in a cost-effective platform. STAX allows companies to: consolidate data acquisition and storage, reduce cumbersome communication and handshaking, reduce control panel size and wiring complexity and expand the pool of available maintenance personnel. Whether it is traditional automation, process control, manufacturing test, or IIoT, STAX brings the cutting edge within reach.

Applications

STAX enables control and data acquisition to coexist in one platform, communicate over the latest digital protocols, and react to new data in real time. Leveraging Signal.X’s 15 years of delivering data-intensive production test systems, STAX brings together the latest technology in a platform built to meet the rigors of the plant floor.

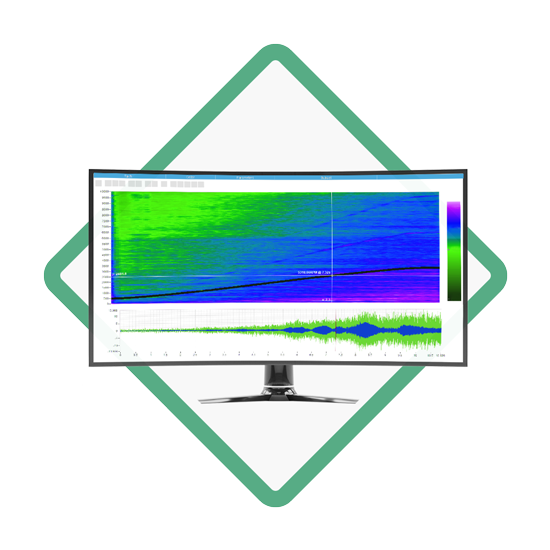

Manufacturing Test

At Signal.X, we define manufacturing test as a category of automation and control systems that requires interaction with a device under test to exercise or simulate test conditions, as well as some method of data acquisition and signal processing to decide if the response indicates that the part was assembled correctly as part of the manufacturing process. This test can happen at the end of line or as part of an in-process verification. Regardless of the type of test, these systems require some degree of both control and signal processing, and they are becoming more and more complex. Years ago, end-of-line test systems were typically made up of a PLC and a PC working together, with the PLC providing the control and automation, and the PC providing the data acquisition and signal processing. However, with continued electrification and increasing complexity, the line between control and data acquisition is blurring—command signals become just as important to track as part of a test record as the system response.