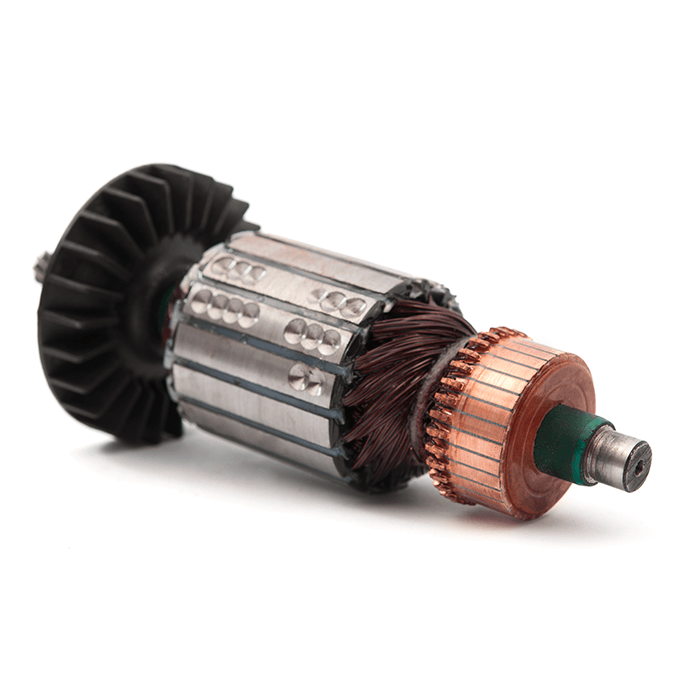

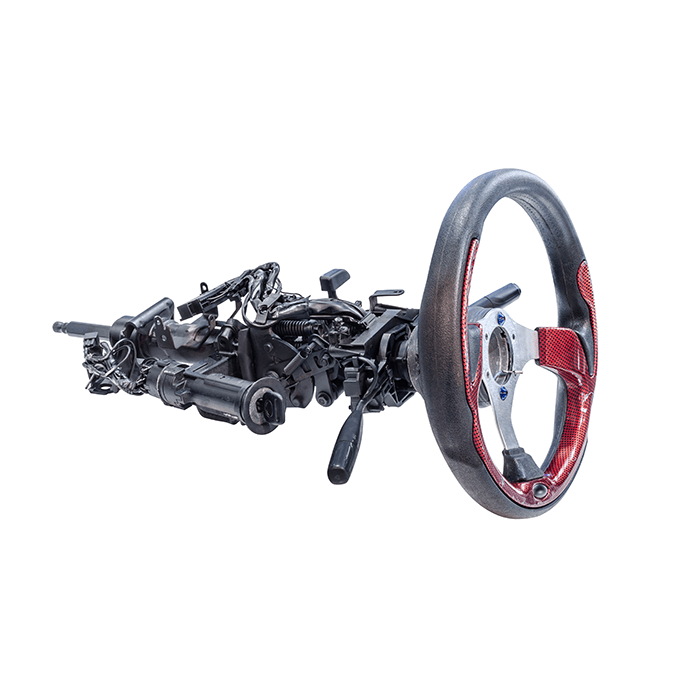

Electric Motor / E-Axle

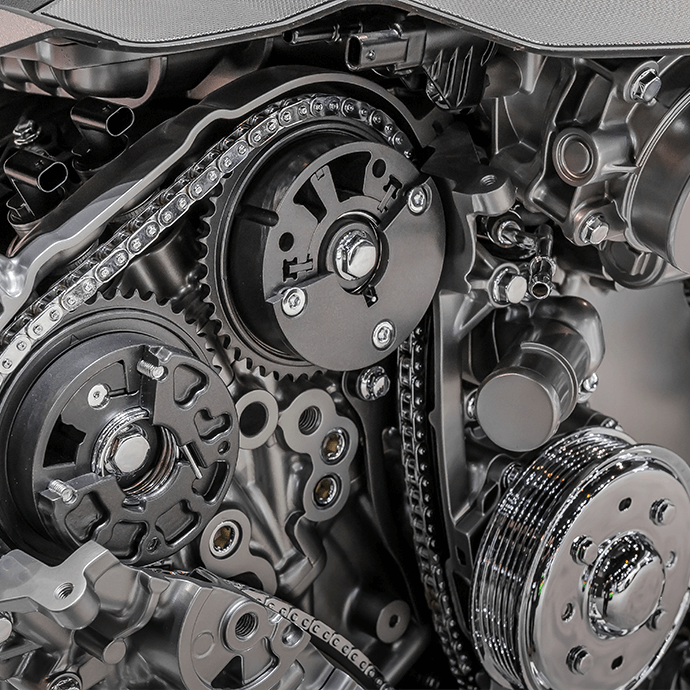

Electric powertrain testing at the end of line represents a blend of traditional axle/powertrain requirements with added complexity and new components. Like traditional EOL axle machines, many of the defects are related to gear mesh, backlash, and order-synchronous phenomena. However, electric powertrains exhibit new electrical defects, require more intimate control of the part under test, and require massive amounts of power flowing to the part under test, which could be palletized. We have integrated battery simulators with industrial drive capabilities for powering inverters.

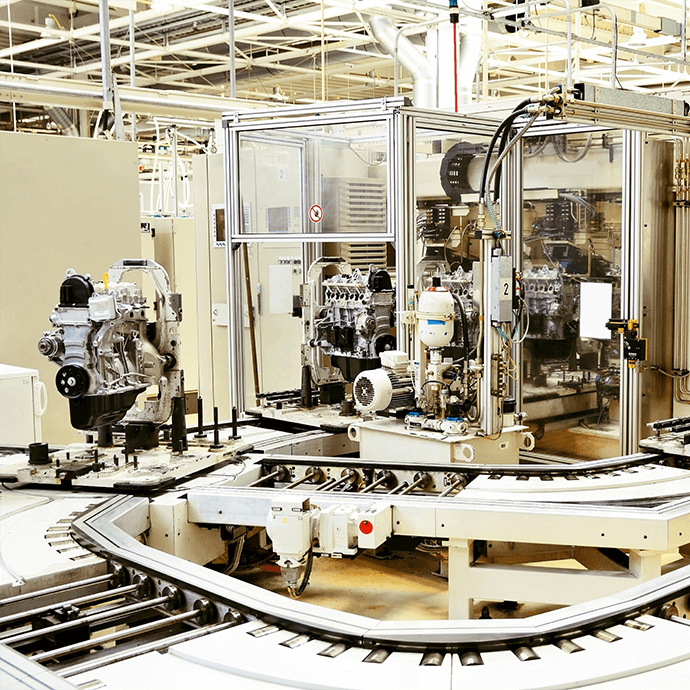

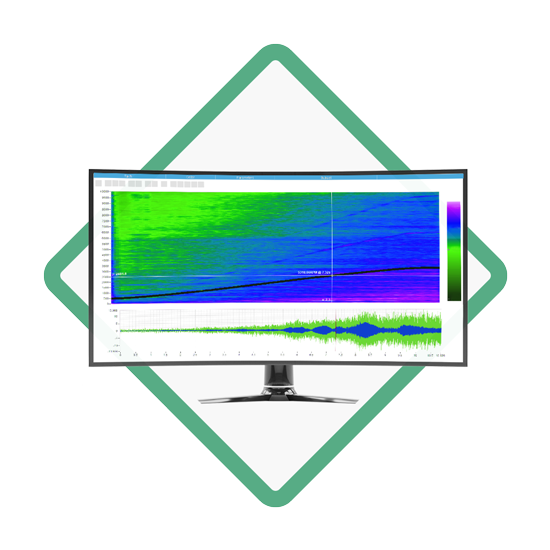

From tooling to isolation to data acquisition, Signal.X knows how to build a successful machine. We also offer integration of NVH measurement with traditional performance-based defect detection.