Machine Concepts

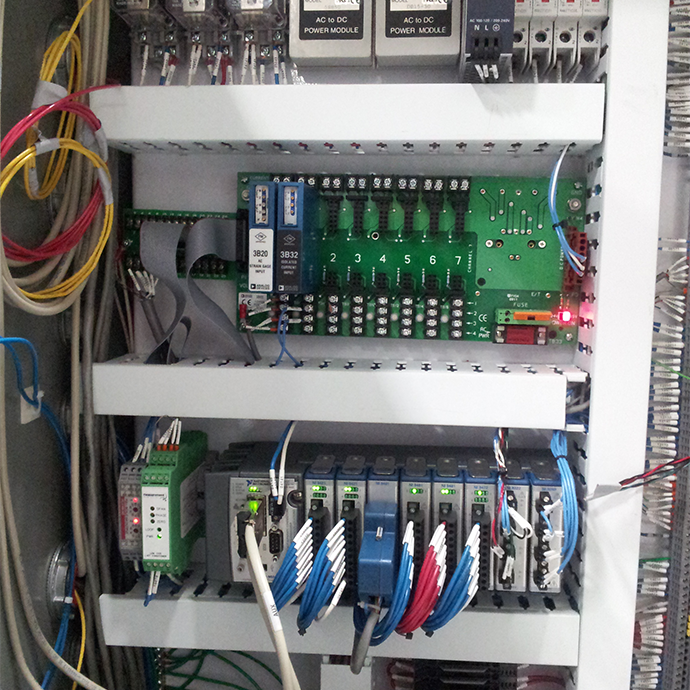

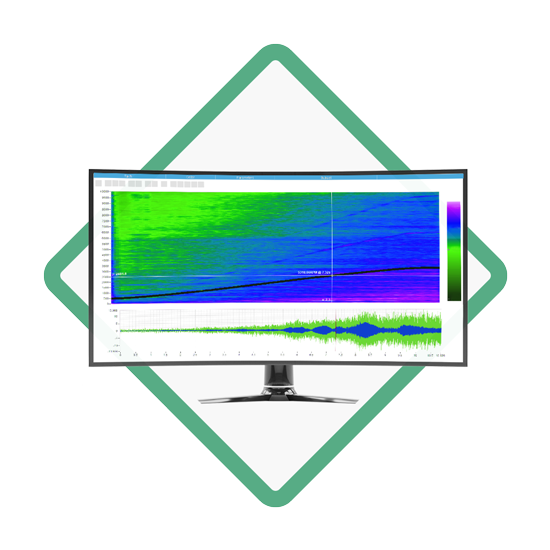

Measure your part, not your machine. As easy as it is to say, this is actually the hardest thing to get right in a production machine, and it is even more critical on an NVH machine. The team at Signal.X brings our experience as mechanical engineers and NVH experts to work with you to build a machine that is repeatable, reliable, and sensitive. From concrete-filled bases to high-accuracy spindles, we understand what makes a machine successful. Using the acquisition system of Shield, we can take advantage of our own accelerometer probe designs, force reaction plates, microphones, torque sensors, and much more.